A MasCot partnership project

About

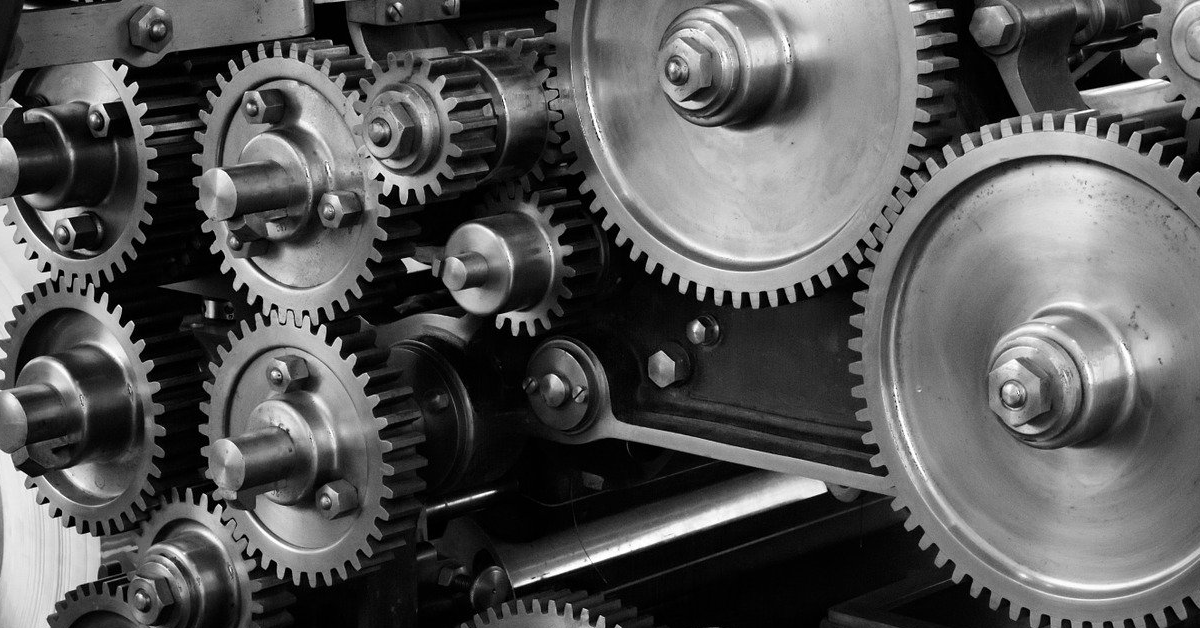

Smart industry targets high quality, highly productive, customizable manufacturing. Optimizing the productivity of Flexible Manufacturing Systems (FMS) is challenging. Today’s FMS are Cyber-Physical Systems (CPS) where productivity depends on the interaction between physical processes, mechanical design and construction, and embedded software and control. Adaptivity and modularity in the FMS design increase flexibility and enable reuse. This improves market potential through product customization and reduces development time and cost through reuse of components and technology. However, adaptivity and modularity complicate optimization of productivity, because design choices and settings for one FMS configuration may not be optimal for another configuration. The SAM-FMS project addresses the challenge of co-designing the mechanical structure and the product flow scheduling of adaptive, modular FMS for optimal productivity. Five specific scientific challenges are investigated:

- (SC1) Modular scheduling and design – How to modularize and distribute FMS scheduling?

- (SC2) Real-time scheduling and design – How to ensure real-time performance of FMS schedulers?

- (SC3) Robust scheduling and design – How to develop schedule(r)s that are robust against variations in operation, configuration, or usage?

- (SC4) Parameterization – How to relate and co-optimize structural FMS parameters (such as transport speeds and buffer capacities) and scheduling parameters?

- (SC5) Schedule(r) learning – How to learn and evolve schedules and schedulers from operational FMS and schedule data?

The SAM-FMS research will be performed in close collaboration with industrial partners Canon Production Printing, ASML, and Vanderlande and research organization ESI (TNO). ESI has a strong valorization track record. We adopt the industry-as-lab model, where an industrial driver case forms the basis for the scientific research. The model ensures that we solve realistic and relevant problems. We then generalize specific solutions to more general principles that also work for other application domains and we validate the results in industrial practice. In SAM-FMS, Canon production printers, like the VarioPrint i300, form the driver.

Results will be validated with Canon Production Printing, for production printing, ASML, for chip manufacturing, and Vanderlande, for warehousing and luggage handling. The collaborations will be realized by weekly presence at Canon Production Printing, by Canon Production Printing hosting a Professional Doctorate in Engineering (PDEng) student, and through joint Master student projects with all three industrial partners.